presentation by Anusheel nahar

OVERVIEW OF PRESENTATION

. controlability with non holonomic inequality constraints

. implementation using grid decomposition for car

like

and tractor trailer robot satisfying

non holonomic inequality constraints

. implementation for a NHR on a natural 3-D surface

like a planetary rover

. jumps for a point NHR using CSC curves

. planning method using jumps

. shortest path accessibility region for a car like

robot that can only move forward

what does a non holonomic constraint mean?

. tangent space(ie set of velocities) of parameters

constrain the motion of robot such that

the resulting dynamic equation is non integrable

with respect to time .

e.g a car like robot cannot move perpendicular

to its main axis

tangent space dx/dt

.sin(theta)=dy/dt .cos(theta)

x= xcoordinate of centre of rear axle midpoint

y= ycoordinate of centre of rear axle midpoint

theta = heading angle of the car

how does NH equality constraint

effect the state of the robot ?

.NH equality constraints reduces the dimensionality

of the configuration space

.if there are k constraints then the dimensionality

is reduced by 1 per constraint

non holonomic inequality constraints

. A car like robot has 2 parameters

that govern its motion/position

velocity of rear wheel v

steering angle

phi

. for most real cars the steering

angle is constrained

-phi

max< phi < phi max

+ve = left turn

-ve = right turn

. radius of turn

R= front_rear wheel

axle seperation/tan(steering angle)=L/tan(phi)

Rmin=L/tan(phi_max)

(velocity of car along

axis)/R= d(theta)/dt

(dx/dt)^2+(dy/dt)^2=(R*(d(theta)/dt))2>=Rmin^2*((d(theta)/dt))2)

so the constraint

(dx/dt)^2+(dy/dt)^2-Rmin^2*((d(theta)/dt))2)>=0

how does a non holonomic inequality

constraint effect

.it picks up a subset of velocity

vectors (x' , y', theta') from the m-k ie (3-1 )

dim tangent space

for the car like / (4-1)tractor trailer robot which satisy the constraint

controllability with inequality

constraints

.for a car like robot

the 2 constraints mean

1.

it cannot move sideways

2. it cannot move on a

radius less than R_min

.if we can define manuevers

which lead to destinations without violating 1

and 2 then we are done.

then given a obstacle

free world we can reach any configuration to any other

just like a free moving

robot having 3 degrees of freedom

formal proof :refer book

manuever 1

1.consists of 3 segments

-arc of radius

= R_min (left) angle =delta theta

-straight line

tangent to the circle1 symmetric about the initial pos(in rev gear)

-arc of radius

= R_min (right) =delta theta

sideways

distance moved= 2*R_min*(1/cos(delta_theta) -1)

this manuever can

be made sufficiently small in terms of the distance moved sideways

by reducing delta_theta.

this mitigates

the effect of constraint 1

2. any amount sideways movement

can be acheived by concatenating sufficient

no. such manuvers(however

small).

manuever of type 2

.consists of 3 segments

- arc of

radius(R_min) by delta theta say towards right

- segment

in rev gear

- arc of

radius(R_min) by delta theta towards right

angle rotated= 2*delta theta

any amount of rotation can be obtained by the above

manuver so effectively

mitigating constraint 2

IMPLEMENTATION FOR A CAR LIKE ROBOT

approach1

generate a path ignoring the NHC using normal methods

like PRM ,potential fields and then try to convert it using the above manuvers

.

-by simeon and laumond

problems

-very expensive

-unreasonable paths obtained

approach2

generate a set of corridors

along which the robot can safely travel and

use the above curves for transferring

between the corridors

problems

-generally very difficult to

define a set of corridors in a workspace

- inefficiencies while trying

to add various interacting curves to get a global solution

approach3

task: reach (x2,y2,theta2) from (x1,y1,theta1)

governing equations

1.x' = v * cos(theta)

2.y' = v * sin(theta)

3.theta' = v/L * tan(phi)

v = speed along the axis

theta = heading angle

on integrating we get

theta(t)= theta(0)+ v/L*tan(phi*t)

x(t)=x(0) + L/tan(phi) *(sin(theta(0)+v/L

*tan(phi))-sin(theta(0))

y(t)=y(0) - L/tan(phi) *(cos(theta(0)+v/L

*tan(phi))-cos(theta(0))

1. discretize and divide the space (x,y,theta) into

3D m*m*m cells grid.

2. we take t=1 and try to integrate along small paths

in the grid

3. we use the parameters v,phi for searching

given a node we generate next 6 nodes s.t

(v,-v)*(-phi_max,0,phi_max)

ie forward Fw, forward left FwL ,forward

right Fwr

and similiarly for backwards Bw,Bwl,Bwr

and integrate the selected pair on a

small path t=1 by putting in the integrated eqn

assumptions

1. robo has only 2 velocities +-v

2. we consider it to go only least radius

4. maintain a tree

a. start node = x1,y1,theta1

b. add the 6 following nodes in

the tree and mark them on the grid as visited

c. generate subsequent 6 and so

on

d. if a node corresponds to intersection

discard the branch

e. if a node is already visited

discard it

f. do so till the cell where the

goal is reached

g the nodes can be added in sorted

order in terms of a cost function

5. issues

. time is taken as 1

. velocity =2*length of a grid element so as

to prevent the robo to stay in the

same cell on any motion and also to prevent

it from going into a cell

farther than 2 cells (this could lead

to collision detection misses)

. cost function = no.reversals (gives

too long path)

. good cost function based on both time and

reversals

6.results

. good results for parallel parking problem

and small maps

with 128^3 cells

. also good for solving locked steering problem

7.complexity

expensive O(m^n * log(m^n))

m = cells per dimension

n = dimensionality of the space

EXTENSION TO TRACTOR TRAILER PROBLEM

1.

governing equations of the model

x1' = vcos(theta1)

y1'= vsin(theta1)

theta1' = vtan(phi)/L1

theta2' = v/L2

*sin(theta1-theta2)

L2= wheel seperation

of trailer and rear wheels

theta2= heading

angle of trailer

2. last equation is non integrable . solved by numerical methods

3.results for 64^4 discretization

IMPLEMENTATION FOR A PLANETARY ROVER ON A 3D SURFACE

1.introduction

-6 wheeled robot on a 3D surface

-having 6 degrees of Freedom

(x,y,z),(roll,pitch,yaw) of the

main frame of the robo

you control the torque on each

of the wheels

2.dimensionality

6+n(due to kinematic/dynamic/friction constraints

of surface/wheel interactions) dim space causing heavy computation time

3. constraints

-geometric obstacles which u have

to avoid at all costs

-other bad areas which may be entered

into but will effect the performance of the

robo like slippery areas

- some wheels have always to be

on the ground

- non holonomic constraints

4.use 2stage approach to find

a safe and executable path

- first generate a global path satisfying

geometric constraints

- locally optimize on it

5. modelling of the robot

- grid of interacting rigid objects satisfying newton

/ euler equations of dynamics

- these objects connected by connectors modeled on

dampers and springs.

- e.g model a revolute joint as 2 pairs of points

1 in each part along the axis of the joint

6 modelling of surface

- as a grid of points with each point being at a centre

of a non elstic sphere

-the surafce as envelope of the spheres

- these points are governed by viscoelastic laws modelled

using dampers/springs/masses

etc

7 geometric path palnning

reduce the problem to 2-D carlike

.ignore terrain effects now

.similiar to the above graph search method

.except instead of taking v,phi,t constants

we do the following

v= ev*v_max

|phi|=ep*|phi_max|

ev<1,ep<1

and keep them constant for a short path.

so you on a radius > min radius

t is chosen such that atleast 1

grid cell is moved in 1 step of node generation.

cell size= 1 robo length in this

case.

8.cost function

takes into account the past and the futurejean

daniel boissonat

euclidean distance may be used

but distance of a curve like C1SC2 circle-segment-circle

can be used

9.dynamic motion planning

aim

.smoothness

.ensure that the robot

can execute a safe path

.the robot may need to

stop at certain points and manuver

to

ensure passage on certain types of terrain. all this makes exact path prediction

very difficult

to overcome these we see that

there are 2 kinds of points

1. manuevering points

where the steering angle changes . velocity < v_max( radius of

curvature,terrain)

2. straight paths where

angular velocity is nearly 0

10 actual physical planning

1. generate a path of CSC type

on a local scale

2. try to apply certain control

torques on the wheels at each incremental steps and analyse

the surface

wheel interactions based on the model. this will show up the

sliding interactions as well and the robo may drift

away from the nominal path

3. assume v and theta to be

constant during each time step delta t

4. if the robot goes too far

from the desired path of CSC type we discard that node and apply

another control

torque to the wheel and do it till a nearly good path is obtained

JUMPS

modeling

. the NHR can be modelled as

a point robot with x,y, theta by appropriately

growing the

obstacles

.given a obstacle free world

a NH robo can reach

any configuration to any other by executing

a curve of CSC

type with radii of circles being the min turning radii

. 4 types of curves

1. Left -Left LL

2. LR

3. RR

4. RL

where the sequence shows the directions of the 2 circles of min turning

radius

a semi free path (one that touches the

obstacles atmost at a finite no. obstacles)

can be broken into a no. subpaths.

-each can be further broken down to represent a jump

recursively if the whole does not

lie in the free space.

-we eliminate subarcs lying entirely in free space

by translation

longer than R_min*pi are made equal to

R_min*pi which may in turn touch an obstacle

shorter ones may be reduced or made into

straight lines. thus a semi free path consisting

of only jumps can be obtained . which

is executable.

algo

jacob and canny

1.we make a set of nodes s.t

if it is a vertex of a polygon

then we consider (x,y,theta(k))

where k= 0,1,2.... 2*pi/delta-1

2. divide each edge into some no. points

the robot can slide along it only

in 2 directions +-theta(e)

include the node (xl,yl,+-theta(e))

3. 2 nodes are connected if using a directed

jump we can reach from a start to a goal

4. path planning can be done by searching the graph

and using some cost function

assume n(e)=linear fn of (1/delta)

no nodes = O(n/delta)

graph building =O((n/delta)^2)

collision check for each jump=O(n)

time complexity= O(n^3/delta^2)

**efficiency can be improved by not counting nodes

which represent vertex and point inside

the obstacle /or is diagonally opposite to such

better use of jumps by using jump graphs

O((nlogn+1/delta)*n^2/delta)

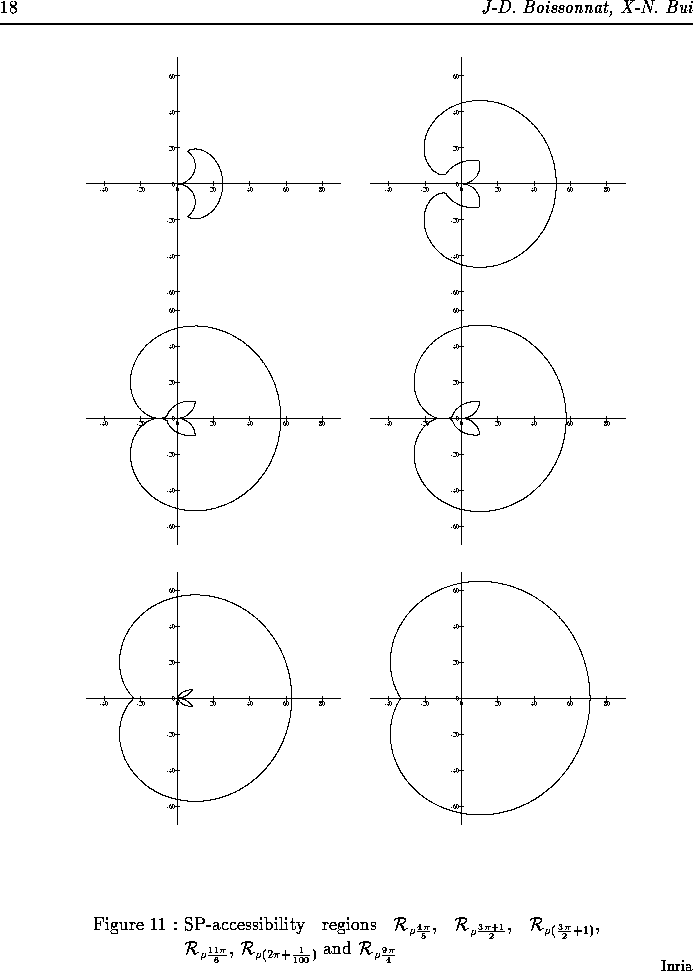

comments on motion of a car like

robot modeled as a point that can only move forward

1.put origin on robot

2. let robo point in positive x axis

3. make circles corresponding to left and r

LS=left straight

LR=right left on (circles)

we consider only +ve y plane .for -ve plane the story

is symmetric

to move to a point in x>0 and lying outside

the circle

.LS is optimal path

.for path on circle L is best

.for path inside the circle x>0

RL is best

.for path on/inside circle on x<0

RL is best

.for others LS is better

d= distance of the optimal path

which can be used to draw the iso distance lines

the arcs x>0 act like a wall the lengths for pointsjust

inside and just outside are vastly different

LvSo

distance=pV

v= angle travelled in left arc

RLv

=p(2pi-v+2/3(pi-v))

applications for

modelling car chasing problems

references

1.jean daniel boissonat INRIA

here

2.cherif laugier

INRIA