INTRODUCTION

Tring Tring...Tring Tring... the phone

rings,one picks up the reciever and calls out into it

....Hello!...irrespective of the caller! A hurried exchange apprises

one of the identity of the caller , and conversation which ensuses is

happily oblivious of the separation between the speakers . Or perhaps

what strikes us - the hostelities much more is the clear voice of our

families providing us with the words of comfort and encouragement , or

perhaps the sweet , seranading voice of each of our girl friends -

when on the phone, constantly titillate us by reminding of relativity

- time seems to fly much too quickly , while those waiting for their

turn , find longer than an unbiased clock would indicate. A

businessman or an executive making deals , or journalist reporting to

his newspaper , a student contacting his professor for advice ,

gossiping amongst friends or perhaps even more frivolously , a wife

calling up her husband every hour to keep a tab on him!

Amid this

gamut of emotions , diversity of cultures and communication across the

miles , what was probably most striking was how we overlooked the

mediums, the instrument the telephone - the product of the marriage

between the disciplines of Electrical & Mechanical engineering.

Thus, an examination of this device , which in its plethora of styles

and forms , has proliferated to almost every home ;is the objective of

our present discussion.

MECHANICAL SYSTEM

BACK TO TOP

DIALLER SYSTEM

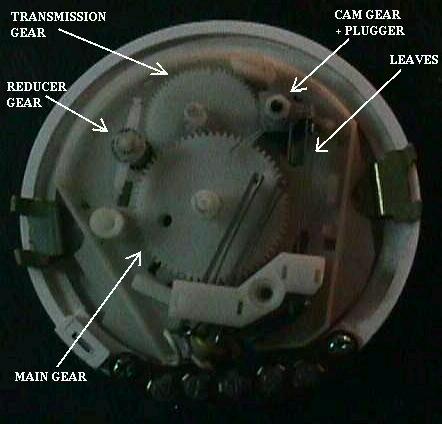

DESCRIPTION OF DIALLER COMPONENTS

1. DIAL

It is a circular plastic disc with small circles cut along its periphery

, through the finger can be passed to actuate the diallling. The sheet of numbers is pasted to the base below it , which remains fixed.

2. MAIN GEAR

It is directly connected to the shaft on which the dial is mounted and essentially transmits to the rotation of the dial to the internal dialling mechanism.

It has two small projections, the pushers; and has 66 teeth.

3.DIALLER SPRING

It is a torsion spring which is connected between the dial and the base. It is this spring which results in the return of the dial once a digit has been dialled.It further provides a limit to the dial by becoming tightly wound around the

shaft.

4. TRANSMISSION GEAR

It is a system of two gears mounted on a single shaft. The smaller one acts as the pinion to the MAIN GEAR

while the larger transmits this motion to the

CAM GEAR

and the REDUCER GEAR.The pinion has 11 teeth

and the gear has 64 teeth.

.

5.CAM GEAR & PLUGGER

The cam gear consists of a gear and a cam on acommon shaft. The gear meshes with the TRANSMISSION GEAR

while the cam transmits the pulse motion to the electrical contacts.

The plugger manifests itself in holding one of the electrical plates fixed, so that the motion of other would lead to an alternating loss and maintenance of contact.

The cam gear has 28 teeth.

6. ELECTRICAL LEAVES

The electrical leaves are in the form of leaf springs, which under normal

conditions stay together. One of these is in contact with the cam of the

CAM GEARand thus moves in accordance with it

.

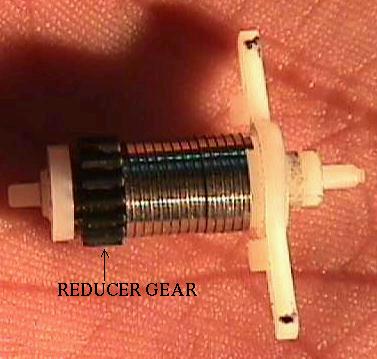

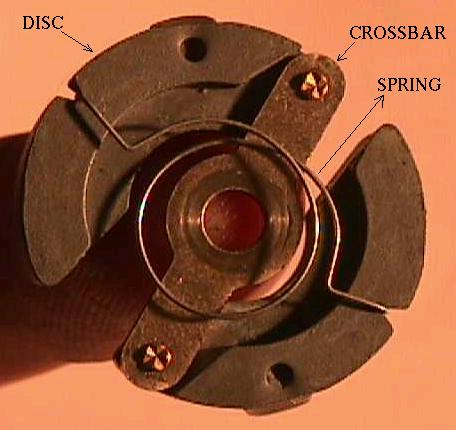

7. REDUCER GEAR

It consists of two separate half discs which are joined together by a crossbar

, which allows the discs to be separated.Thsese are held together by a spring .This arrangement accomodates one of the reducer gear which transmits motion

to & from the reducer.The reducer is enclosed within a circular ring, the

inside of which is metallic.The reducer gear has 16 teeth.

BACK TO TOP

MECHANISM OF DIALLER

The dialling mechanism is that part of the telephone instrument which

converts the information of the dialled telephone number into electrical impulses which are thus transmitted to the exchange for the required connection.

The impulses as mentioned above are electrical in nature and are generated

by the alternating loss of contact and making of contact of the electrical leaves. The contact is broken as many times as the dialled digit.( the explanation of which will follow shortly)

The electrical leaves act as leaf springs, which are prestressed such that normally remain in contact. The inner leaf presses against the cam throughout

the dialling cycle and thus as the cam rotates , the inner leaf oscillates along with it. If the outer leaf is free to move , it would remain presses against

the inner leaf , thus moving along with it and maintaining electrical contact.

But , if the outer leaf is held back physically;as the inner leaf oscillates it would alternately make and break contact with the outer leaf, thus generating

the impulse signal. This , precisely forms the basis for the working of the

dialling mechanism.

Having understood the basic principle behind the dialling process , we now proceed towards a logical , step by step explanation of the actual process from

the dialling of the number through dialler to the generation of the electrical impulses at the electrical leaves.

CONSTRUCTION

The main gear meshes with the smaller one of the transmission gear,the

larger transmission gear meshes with the cam gear and the reducer gear.The

reducer gear shaft is attached with a reducer, which consists of two half disks.The plugger is attached with the cam gear shaft.There is a spring attached to

the base of the main gear shaft which brings back the dialler to its original

position after the number has been dialled.

DIALLER MECHANISM

The process of dialling a digit begins with the turning of the dialler by the

caller . This directly results in two things - first ,precisely the same motion is transmitted to the main gear

which is mounted on the same shaft as the dialler and second , it gives rise to stressing of the dialler spring which would bring the dialler back when it is released.

Let us at this point, divide the dialling cycle into two parts:

(a) The dial stroke during which the cradle rotates the dialler.

(b) And the release stroke during which the dialler returns to its original position by virtue of the spring torque of the dialler spring .

Consider the dialing mechanism from the BACK side , thus revealing the internel mechanism.During the dial stroke the main gear rotates anticlockwise which thus rotates the

transmission gear clockwise which in turn rotates the cam gearanticlockwise.This leads to the following:

(a)the plugger, which is situated on the cam gear and is linked to it by friction thus tries to rotate anticlockwise too and hence remains at one extreme position - the position at which it doesn't hinder the motion of the outer leaf.

(b) and since the plunger doesn't interfere with the outer leaf , it continues to move along with the inner leaf, thus maintaining contact throughout the

dial stroke . The inner leaf ofcourse maintains contact with the cam and thus oscillates along with the rotation of the cam.

The dialling stroke is complete when the caller has turned the dial by the appropriate amount.This information is stored in the dialler spring and gets

converted into the electrical signal finally , to be sent to the telephone exchange

Next as soon as the caller releases the dial ,the

release strokecommences.As mentioned earlier , during this stroke the dial

is brought back to its original position by the torsional dial spring. This

rotates the main gear in the clockwise direction which moves the

transmission gearin the anti clockwise direction which in turn rotates the

cam gear

in the clockwise direction.This leads to the following:

(a) the plugger, which is located on thecam gear and linked to it by friction also rotates in the clockwise direction along

with the cam gear until it comes to its clockwise extreme position wherein it

fixes the position of outer leaf , constraining it.

(b) this leads to the making and breaking of contact between the leaves as explained in the "basic principle of impulse generation"

The amount of turn of the dial dictates the number of revolutions of the cam

gear and hence of the cam.�nd this guides the number of oscillations of the

innerr leaf and thus the number of pulses. And the accordance betwwen the number of dials and the pulses is maintained.

The release strokeis completed when the

knocker on the main gearknocks the plugger

to make it to rotate anticlockwise, thus releasing the outer leaf, bringing

the impulses to an end.Finally the release stroke is completed with the knocker separating "New number electrical leaves".Thus passing the information that

the process of dialling of digit is complete and hence bringing the dialling

mechanism to its original state,ready to accept a new digit in the form of a new dialling cycle.

Finallly to explain the role of the "reducer."The reducer is designed from

dynamic consideration.When the dial is released , during the release stroke

,it is the dialler spring that rotates the system.If allowed to unwind on its

own it would lead to the attainment of a high velocity(kinetic energy) by the

system leading to a more severe collision at the end of the cycle,leading to

greater stresses and quicker wear and tear.To avoid this is precisely the

function of the reducer.It essentially acts as a coloumb damper(friction

damper)and thus dissipates some of the enenrgy stored in the spring during the

release stroke.

It works as follows:

Motion is transmitted to the reducer by the reducer gear which is rotated by the transmission gear

which in turn is imparted motion from the main

gearThis gear train ensures that the reducers rotates at 24 times the

angular velocity of the main gear. At such a higher anguler velocity the

centrifugal force on the half discs, tends to move them apart, bringing them outward and thus leading to the pressing of the friction heads upon the metal ring,thereby dissipating energy in the form of friction.

BACK TO TOP